At first glance, mushrooms and cars don’t have a lot in common. But that could change down the road, bringing labour savings for farmers and more mushrooms to market for Canadians.

Using concepts long used in automotive manufacturing, researchers at the Vineland Research and Innovation Centre (Vineland) have developed a robot to pick mushrooms. It’s still in the prototype stage, but John Van de Vegte, Vineland’s Robotics and Automation Project Manager, says it has the potential to change the entire mushroom growing industry.

Currently, mushroom farmers depend on a large workforce to harvest their crop by hand. The hours are long and the work is hard, making it difficult to attract and retain employees.

“Harvesting is where automation could have a definite effect on the mushroom industry. It is challenging to train staff to perform repetitive work,” he explains. “We want to shift the jobs from picking to higher paying positions like technicians who can run and service the machines, for example.”

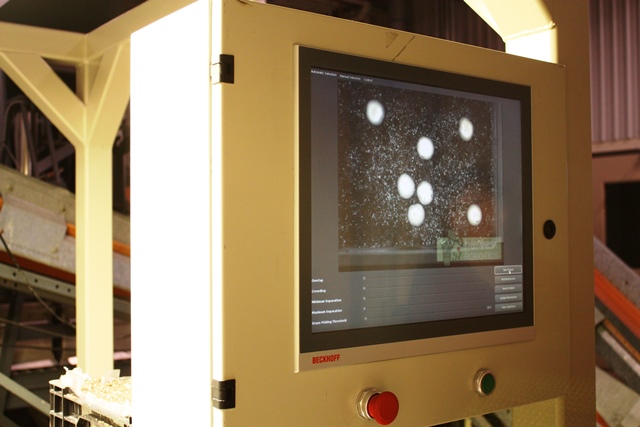

Mushrooms are grown in beds, stacked on top of each other, using spores and a compost-like medium called substrate. Once seeded, the beds are moved into a growing room where farmers create the proper environmental conditions for mushrooms to grow – the right combination of humidity, temperature and carbon dioxide levels. Vineland’s automation system allows the user to set specific rules about what type of mushrooms to pick and when, letting farmers optimize their production to get more pounds of mushrooms per square foot.

“Mushrooms are different sizes and people want perfect, round mushrooms with no marks or dents,” says Van de Vegte. “For example, button mushrooms are the small ones that are removed so other mushrooms can grow larger.”

When it’s ready to harvest, the robot moves over top of a bed of mushrooms and, using an image of the bed and the picking rules it has been given, gently plucks each desired mushroom from the bed, de-stems it and drops it into a store-ready container.

Van de Vegte gives a lot of credit to a local mushroom grower for letting Vineland’s team access his facility and helping them understand how mushrooms are grown and harvested. Not only does any machine replacing a human process have to be at least as quick and as accurate, it also has to be affordable for farmers. “Our functionality has to be tied to cost. We don’t want a great system that nobody can afford,” he says.

The next step for Vineland’s mushroom harvest system is a small scale production pilot in a commercial mushroom farm to help Van de Vegte understand the quality and productivity of the system and how it could best be implemented. It’s important they proceed slowly and carefully, he says, so they’re not rushing to market with a technology that isn’t ready. Long term, Vineland’s objective is to license the intellectual property and then market it worldwide, with the resulting royalties being used to fund future research. Vineland’s automation team is working on other systems as well, two in particular for the ornamental flower industry.

One machine can put colourful plastic or paper sheets, labels and sleeves on about 500 potted plants per hour to ready them for market, and another can transplant plant cuttings and bulbs from trays into individual pots. Both jobs are currently done manually by workers. All three systems are made-in-Ontario solutions, with Vineland partnering with local firms to assist with various stages of development or production. The current project focuses on technology for mushroom and ornamental greenhouse growers, but Van de Vegte says in future, they’d like to expand into orchards and vegetable greenhouses as well.

The automated systems program at Vineland is supported through FedDev Ontario, with Vineland’s in-kind contributions supported by an investment in Vineland through Growing Forward 2, a federal-provincial-territorial initiative.

Source: AgInnovation