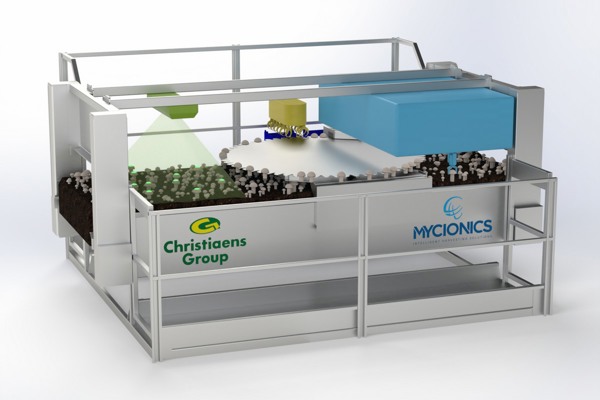

According to a Christiaens Group press release the Heereco, a pioneer in organic mushroom cultivation in the Netherlands, is implementing the most fully integrated automated solution for mushroom harvesting in the fresh market. This groundbreaking achievement is realized through the strategic integration of Christiaens‘ future-proof Drawer System and Mycionics‘ advanced robotic technology, including the pointer system.

Collaborative automation

In collaboration with Mycionics, Christiaens Group showcases a fully automated solution for mushroom harvesting up to the packhouse. Christiaens’ future-proof Drawer System, combined with Mycionics’ state-of-the-art robotic technology, marks a significant advancement in the field. Mycionics’ robotic picker, working in tandem with human efforts, demonstrates the capability to harvest mushrooms at twice the speed. This not only boosts productivity but also reduces reliance on human labor, resulting in increased crop yields and superior quality at a reduced production cost. The integrated robotic picker, coupled with the Christiaens platform, promises a fast return on investment.

A short video on how the Drawer System works can be viewed by clicking HERE.

Automation in the packaging process

To further enhance automation, Christiaens mushroom packer and box conveying system revolutionize the packaging process of mushrooms. This automated system efficiently places mushrooms into containers and transports them for packing and shipment preparation. It brings consistency and efficiency to the packaging process, raising the bar for excellence in mushroom farming.

Supporting harvest personnel

Mycionics’ Pointer System creates an optimal interaction between robot and human. Improving harvesting efficiency, reducing training time for new pickers and minimizing picking errors.

Next to that, big data offers real-time information about the mushroom bed, including: size, microclimate, growth rate and quality, adding invaluable insight to the cultivation process.

Game-changer in productivity

Christiaens’ Drawer System, enhanced with robotic capabilities, emerges as a game-changer in farm productivity. Demonstrating the potential to enhance both quantity and quality of mushroom crops, this system outperforms traditional shelf farms reliant on manual labor, offering a remarkable fast return on investment and a significant advancement in mushroom farming efficiency.

“Our commitment to organic cultivation and innovation creates that we partner only with the best in the market for automated mushroom harvesting. This groundbreaking technology of Mycionics and Christiaens enhances our productivity and aligns seamlessly with our dedication to sustainability. We believe this marks a transformative moment in the future of mushroom farming.” – Jeffrey Heeren (Owner Heereco).

———————————————————————————————————————

Heereco

Heereco is a leading organic mushroom cultivation company known for its commitment to sustainable farming practices and continuous innovation. With 12,000 square meters of production on 3 sites, Heereco combines environmental consciousness with cutting-edge technology.

Mycionics

Mycionics is a leader in the development of robotic solutions for the agriculture industry. With a strong commitment to innovation, Mycionics is dedicated to enhancing agricultural processes, increasing efficiency, reducing labor dependency through cutting-edge robotics technology.

Christiaens Group

Christiaens Group is a global leader in innovative solutions for mushroom cultivation, organic waste composting and mycelium products. With a rich history of innovation, Christiaens Group is dedicated to shaping the future of mushroom farming through forward-thinking concepts and technology integration.

https://www.christiaensgroup.com/

Source: Christiaens Group